Test Systems

Individual solutions for quality testing of semiconductors

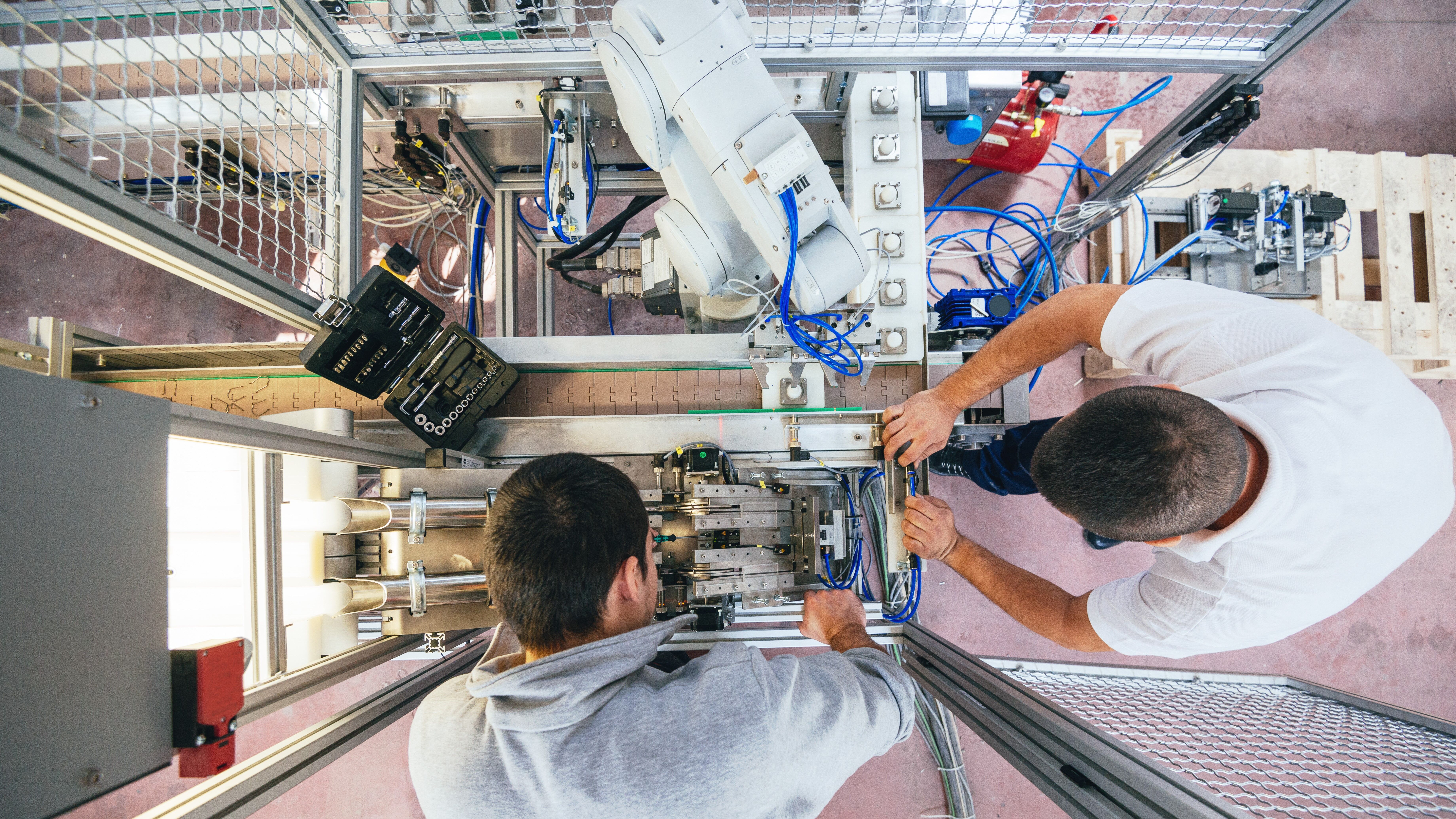

Automatic measuring machines and test systems are used to check quality during the production of power semiconductors or assemblies and to carry out complex measuring tasks fully automatically. We offer you a wide range of different test systems that can be used to test and measure a wide variety of parameters and characteristics of components and assemblies. Our services include the custom development of systems according to your requirements as well as the worldwide initial set up of finished systems on site.

Test systems for power semiconductors

Whether large automated test systems that are integrated into the production line or manually operated systems for small batches. Depending on size or functional requirements, we also create individual test systems with mechanical marking, laser marking or with inkjet marking.

Markets

Automotive

Renewable Energy

E-Mobility

Industry

Testers for different requirements

The more extensive and complex the power electronic components, the more demanding the requirements on today's test systems. We offer test systems for different applications, always with the option of customization.

Parameter tester

Parameter tester record detailed electrical parameters and provide comprehensive data for checking limit values, optimizing production processes and for quality documentation.

Test systems for single power diodes

Measure all diode-parameters including power, such as

- Contact check

- Vz temp. compensated

- IR / DIR temp. compensated

- Vf (mA), Vf (Power)

- dVf (ZHT)

Handling system with

- Bunker

- Feeder

- Headwire straightener station

- Cutting station

- Measuring of cutting length

- Measuring station

- Marking station

- Good / waste sorting

Test systems for half bridges/rectifiers

Measure all parameters of the power-diodes in a halfbridge/rectifier such as

- Contact check

- Vz temp. compensated

- IR / DIR (with leakage current compensation)

- Vf (mA)

- Chipfactor

- dVf (Loading)

Handling system fully automated or manual draw stations with exchangeable adapter-system, marking, good / waste differentiation and waste box with sensor.

Test systems for FET modules

Measure all parameters of the FETs on the module such as

- Contact check

- VSD diode

- BVDSS

- IDSS and DIDSS (forward/reverse) with leakage current compensation

- IGSS / DIGSS

- VGSTH

- RDSON

- ZTH, ZTH loop

- C-Capacitor

- R-Resistor, R-Shunt

Integrated avalanche tests (avalanche test with VBAT max. 90 VDC). Integration into a fully automated handling system.

Parameter test systems for IGBT modules

Measure all parameters of the IGBT’s on the module (up to 1000A) such as

- Contact

- VSD diode

- VCE, VCESAT

- ICES / DICES (forward/reverse) with leakage current compensation

- IGES / DIGES

- VGSTH

- ZTH, ZTH loop

- C-Capacitor

- R-Resistor, R-Shunt

Integration into a fully automated handling system.

Dynamic tester

Dynamic tests such as double pulse tests (RBSOA) and / or short circuit tests (SCSOA) are used to test the performance and durability of IGBT modules (Si, SiC, GaN) - essential for applications in power electronics. These tests can be carried out at room temperature and / or at maximum temperature.

Tester cabinet

Control of the measurement unit and accurate data logging with the highest possible resolution. Including external oscilloscopes for analyzing the measuring results like: du / dt value, di / dt value, switching times, clamping voltage, peak voltages, collector current, gate voltage.

Complete traceability of each DUT for later analysis saving the measuring data in databases with upload to the company network if necessary.

Measurement unit

Measurement unit up to 1500 V / 4000 A RBSOA and 1500 V / 12000 A SCSOA.

- Measuring equipment adapted for each product to get the highest possible resolution.

- Customized DC link for each DUT to minimize ESL.

- Individual gatedrive stage.

- Contact check unit to ensure the DUT is properly connected before applying high voltage.

- Short circuit detection option to prevent uncontrolled discharging of the DC link into the system during a DUT failure.

- Very low stray induction of the complete system otherwise it will be just switching without real stressing during switching.

- Integrated into a fully automated shift-operation production line.

Examples of our dynamics testers

Example of laboratory configuration

Example of automatic inline configuration

Customer Specific Testers

Tailor-made solutions that cover special test procedures for a continuous quality control during the production. These tests ensure that components function reliably even under extreme conditions.

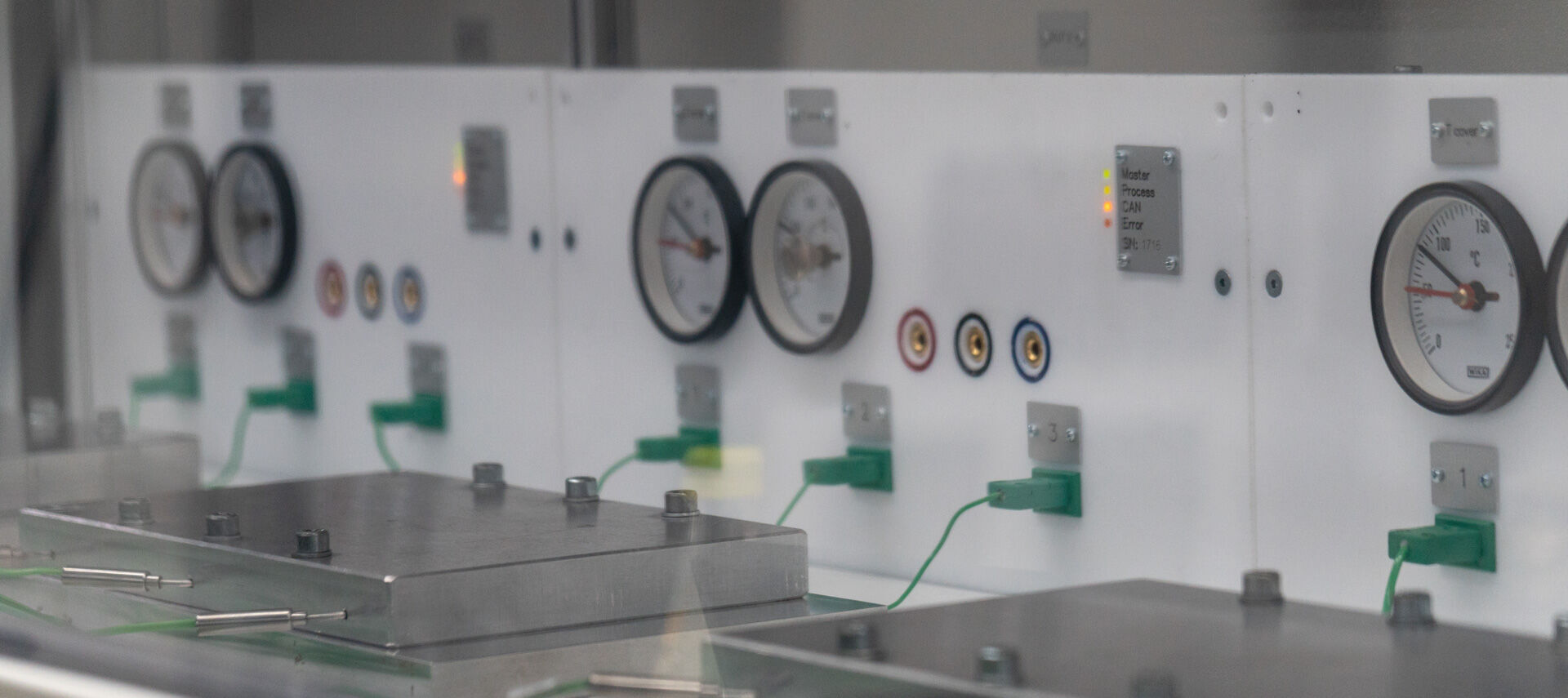

HTRB test system

A very compact test system for carrying out High Temperature Reverse Bias tests, which is capable to test 4x DUTs with up to +/- 6500 V at max. 200 °C.

- The test system works for 72 hours independently of the PC (in case of PCshutdown)

- High voltage power supplies

- A standard meter to monitor the current and voltage

- 4x temperature regulators

- Separate heating and cooling for each DUT

ZTH test system

Low volume production line ZTH test system with 150 A. Testing all parameters of a FETmodule such as:

- Contact check

- VSD diode

- BVDSS

- IDSS and DIDSS (forward / reverse) with leakage current compensation

- IGSS / DIGSS

- VGSTH

- RDSON

- ZTH, ZTH loop

- C-Capacitor

- R-Resistor, R-Shunt

HTOL test system

The DUTs are cycled for a specific time (100 h - 1000 h), most of the time under high temperature in a heating chamber. Different JEDEC standards define the individual test for each DUT which is interpreted by the hardware and software. The complete test is interpreted by analysis tools.

- High power supplies and a standard oscilloscope to monitor the current and voltage

- Multiplexer to switch each DUT to the scope for V-measurement

- Current-limitation for each DUT

- Separate contacting for the 80 DUTs placed into a heating chamber up to 260 °C

Thermal cycle diode tester

Rectifier diodes (DUTs) are stresstested with high-current pulses (up to 200 A) while monitoring forward voltage to determine internal temperature. Afterwards the rectifier diode is cooled down to a given

forward voltage start value and repeats the test. Each of the 16 independent test positions runs for over 500 hours with programmable cycles and cooling phases.

- Custom voltage and current classification per customer specs

- Programmable cycle patterns

- Independent test positions for parallel testing

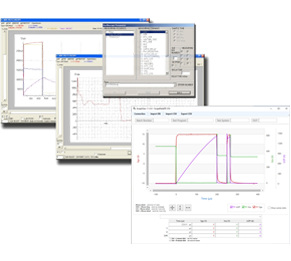

Software

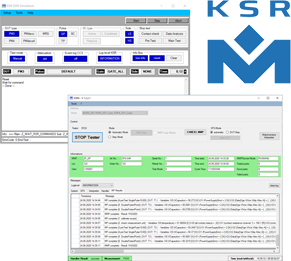

Operating Software (KSR32 / KSR4) Application

- Controls the hardware components of the tester

- Loads the measuring programs

- Performs the measurement process

- Handles other PC-Software e.g., integrated scope function

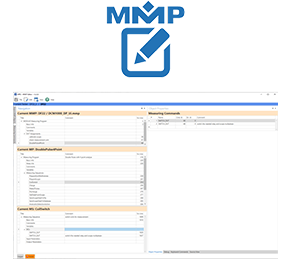

Module Measuring Program Editor

- Measuring programs are easy to change (save money and time)

- Measuring programs are compatible

- Exchangeable between testers

Integrated Oscilloscope

Display of the measurement data with zoom and editing function for ideal measurement data analysis.

Automatic calibration tool

How is a MRS tester calibrated?

For calibration, this module is simply measured using a suitable reference instrument. The result is then transmitted to the tester and stored in non-volatile memory — completely eliminating the need for manual adjustment using potentiometers.

To simplify the process, we provide a dedicated tool for automatic calibration. This tool works in conjunction with a calibrated digital multimeter and additional circuitry to cover all relevant measurement ranges.

Especially for our international customers, this solution enables independent calibration and periodic verification of the tester’s DC specifications. A detailed calibration report is generated automatically, comparing the values from the tester and the reference multimeter.

Your advantages with MRS test systems

Knowhow and experience

We have decades of experience in testing power semiconductors.

Individual test systems

Since all components of MRS systems are modular, individual systems can be created flexible and completely according to your requirements.

Test systems worldwide

Long-term cooperation with worldwide well-known customers from various industries.

Made in Germany

Modern manufacturing technologies as well as compliant quality standards - We develop and produce in our facility in Germany.

Machine directive

Our MRS Test Systems comply with the CE standard and are built according to the specification of the Machinery Directive 2006 / 42 / EC: DIN EN 60204, DIN EN ISO 12100, DIN EN ISO 13849.

Contact

Would you like to learn more or are you looking for a specific test system?

Then feel free to contact us.